Within the alternative fuels sector, there are many solutions that can be utilised to help reduce our use of fossil fuels. One of those is e-fuels. In this article, we’ll explore what e-fuels are, how they’re made and where they can be used to help combat climate change.

What are e-fuels?

E-fuels, or electrofuels, are a specific type of synthetic fuel. They are made using green hydrogen (hydrogen that’s produced using renewable electricity like solar, wind, or hydro) to electrolyse water, rather than using a fossil fuel, such as natural gas, to produce the hydrogen.

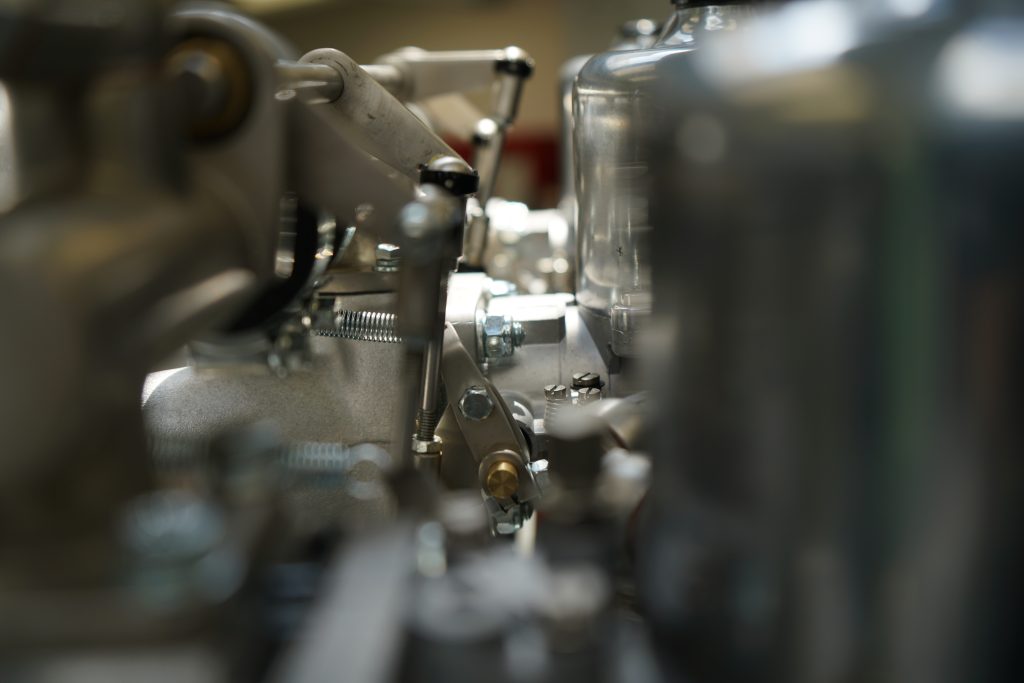

Compatible with most internal combustion engines (ICEs), e-fuels mimic the properties of conventional fossil fuels without the need to release new carbon from the ground. As a result, they sit alongside other sustainable fuels such as biofuel as a potential solution for transitioning away from fossil fuel in sectors where direct electrification is difficult, such as shipping, aviation, and heavy industry.

What’s the difference between e-fuels and other synthetic fuels?

Generally, the term ‘synthetic fuels’ refers to man-made liquid or gaseous fuels produced through chemical processes that convert raw materials into hydrocarbons through processes like Fischer-Tropsch synthesis. Synthetic fuels don’t necessarily have to aim for carbon neutrality, and their feedstocks can be renewable (e.g. biomass) or fossil-based (e.g. coal or natural gas).

E-fuels fall under the synthetic fuel category, as they are made using chemical building blocks produced by industrial processes. However, they must use electrical energy from renewable sources.

How are e-fuels made?

E-fuel production involves converting renewable energy into synthetic hydrocarbons through various chemical processes.

- Renewable energy generation: The process begins with generating renewable electricity from sources like solar, wind, or hydropower. This clean energy is essential for powering the production of hydrogen, the key component of e-fuels.

- Water electrolysis: Next, this renewable electricity is used to split water (H₂O) into hydrogen (H₂) and oxygen (O₂) through electrolysis.

- Carbon dioxide capture: After this, CO₂ is captured either directly from the atmosphere using Direct Air Capture (DAC) technology or from industrial emissions. This captured CO₂ is the source of carbon needed to create synthetic hydrocarbons.

- Hydrocarbon synthesis: The hydrogen produced in electrolysis is combined with the captured CO₂ to create hydrocarbons. This can be done using methods like the Fischer-Tropsch process, where hydrogen and CO₂ are reacted under high pressure and temperature to form long-chain hydrocarbons. Alternatively, it can be done through methanol synthesis, where hydrogen and CO₂ are combined to produce methanol, which can be further processed into fuels like gasoline or diesel.

- Refining: The hydrocarbons are then refined into specific types of fuel such as synthetic gasoline, diesel, kerosene (jet fuel), or methane for natural gas engines.

Where are e-fuels used?

The characteristics of e-fuels make them suitable for many applications. Some examples have been listed below.

- Aviation: E-fuels like e-kerosene are being developed to help reduce the carbon produced by the aviation industry, which is difficult to electrify.

- Shipping: E-fuels could power large ships, replacing fossil-based marine fuels.

- Automotive: E-fuels could be used in conventional internal combustion engine vehicles as a drop-in fuel, extending the life of existing vehicle fleets.

- Industry: E-fuels could be used in high-temperature industrial processes where electrification is impractical.

What are the pros and cons of e-fuels?

Like all technologies, e-fuels have their strengths and weaknesses. Some of the advantages of e-fuels are listed below.

- They recycle carbon: Since the CO₂ used in their production is captured from the air or other sources, burning e-fuels releases only the CO₂ that was originally captured, resulting in no net increase in atmospheric CO₂.

- Compatibility: E-fuels can be used in existing internal combustion engines (ICEs) and other infrastructure without significant modifications, which makes them attractive for sectors that are hard to electrify. This includes the aviation industry, although there are specific criteria aligned to using e-fuel technology in aircraft.

- Energy storage: E-fuels store renewable energy in a chemical form, which can be used when electricity generation from renewables like solar or wind is intermittent.

What are the challenges of facing e-fuels?

Here we list some of the challenges presented by e-fuels.

- Energy-intensive production: The production of e-fuels requires a lot of renewable electricity, and the conversion process from electricity to fuel is less efficient than the direct use of electricity. However, in places where there is an excess of renewable energy, it is better to use that excess to produce e-fuels rather than waste it. E-fuels are easier to transport to where the energy is needed than electricity.

- Cost: E-fuels are currently more expensive to produce than conventional fossil fuels or even some biofuels, though costs are expected to decrease as technology improves and scales up.

- Limited availability: The commercial availability of e-fuels is currently limited due to the early stage of development and high costs, but there are ongoing pilot projects and investments in scaling production.

So there you have it, e-fuels explained. For more information on alternative fuels and sustainable motoring, please visit our pages within the education hub, where you’ll find all our latest articles and insights.