Mass-balanced, co-produced, and co-processed fuels are three key fuel production processes that offer practical, scalable solutions for the sustainable fuel industry by integrating renewable and fossil feedstocks within existing refinery infrastructure. These three different methods optimise resources, reduce emissions, and increase the supply of lower-carbon fuels, paving a pragmatic path toward a sustainable energy future without requiring new facilities.

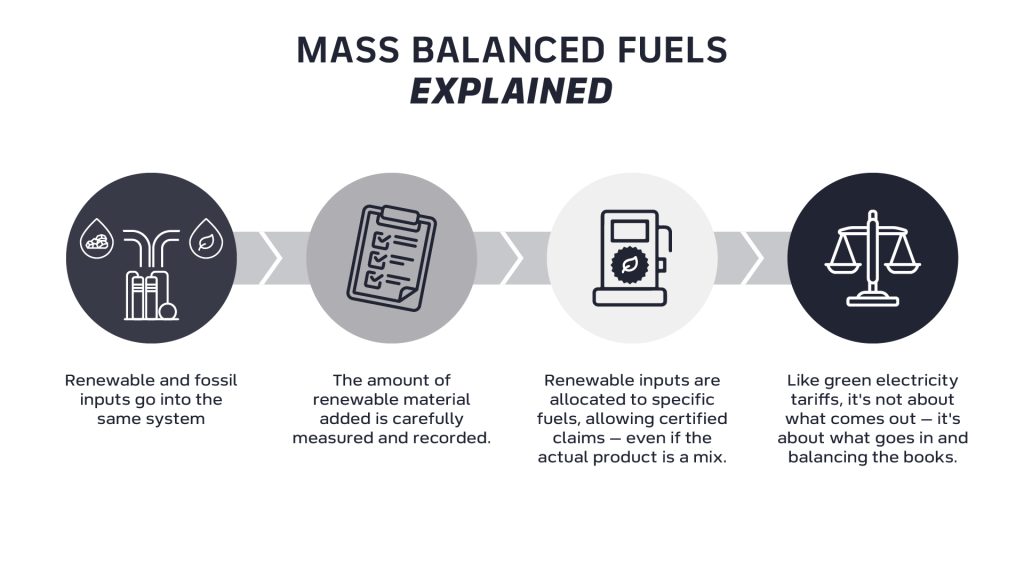

Mass Balanced Fuels

Mass balancing can be used to certify a fuel as 100% fossil-free when, in reality, the product you receive may have carbon molecules in it that are not renewable. The process involves carefully tracking the volume of renewable materials introduced into the system. These renewable inputs are then allocated to specific fuels, allowing manufacturers to claim a portion of the final product as renewable, even if the physical fuel contains a mix of fossil and renewable molecules. This approach does not guarantee that the fuel delivered to the end user is entirely fossil-free, but it ensures that an equivalent amount of renewable fuel has been introduced into the supply chain, effectively displacing fossil fuel use.

In simple terms, manufacturers can integrate fossil and renewable feedstocks within the same production system by utilising existing refining and distribution infrastructure to maximise efficiency and minimise costs.

By keeping track of the quantities of renewable content and then allocating that amount to certain products, you can gain verification of the content through third parties, such as the International Sustainability and Carbon Certification (ISCC) chain of custody mass balance system, and audit and verify that the renewable content claimed aligns with the actual renewable inputs.

This is similar to the concept of green electricity tariffs. You may pay for a green tariff, but that doesn’t mean the electricity coming through your sockets is any greener than that of your neighbour on a standard tariff. This means that we keep score of how many green electricity units have gone into to the grid and these are allocated to users according to their tariff. We just have to make sure the scores tally up at the end.

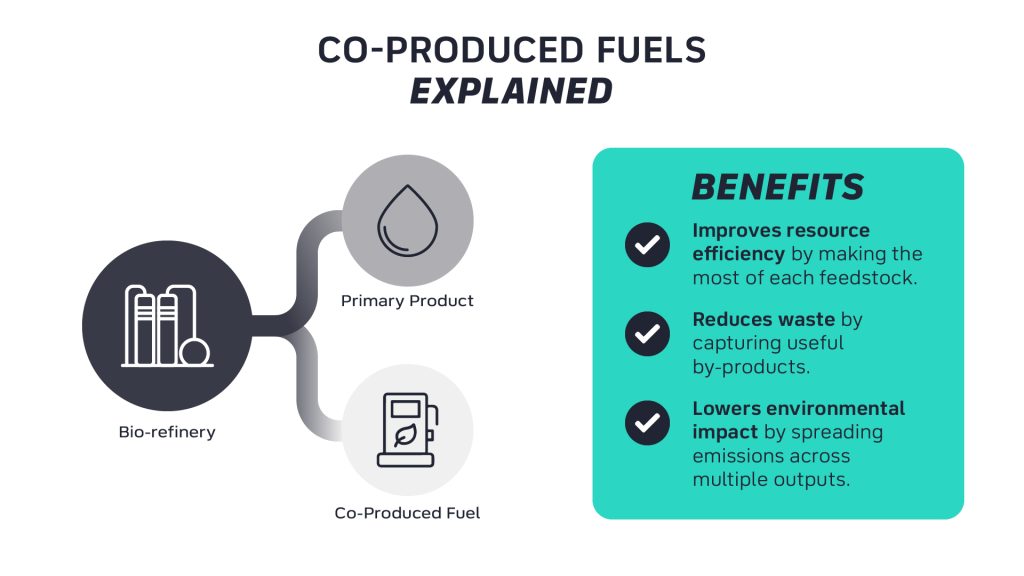

What are co-produced fuels?

Co-produced fuels are fuels generated as secondary or incidental outputs during a manufacturing process primarily designed to produce another product. For instance, in bio-refineries the production of biofuels might result in co-produced fuels alongside primary products like ethanol or biodiesel.

This approach enhances resource efficiency by extracting multiple usable products from a single feedstock or process. Therefore reducing waste and optimising the use of raw materials. This can also lower the overall environmental impact by spreading the energy and emissions footprint of the manufacturing process across multiple outputs, making each product more sustainable than if it was produced independently.

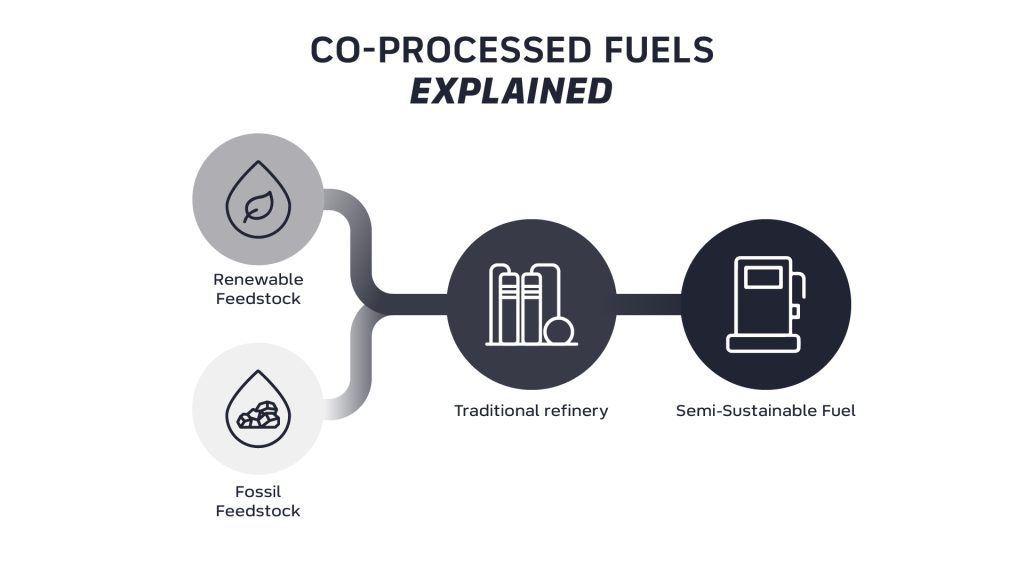

What are co-processed fuels?

Co-processed fuels are the combination of renewable and fossil-derived feedstocks in a single production process. Often using a fossil-based catalyst or other components to facilitate the reaction. For example, renewable feedstocks like vegetable oils or animal fats might be co-processed with regular fossil-based petroleum in a traditional refinery to blend into a new fuel that contains both sustainable and non-sustainable elements.

This results in a semi-sustainable fuel that reduces reliance on fossil fuels, contributing to incremental improvements in sustainability. While still being compatible with existing refining technologies and infrastructure, without requiring significant modifications to equipment or processes.